Glass

Our unique and innovative glass-working tools deliver exceptional results and optimal value for money. If you can't find what you're looking for, please contact us (link to contact form) and let our expert advisers help you find the right solution for your needs.

For more information, download our product guide here.

Architectural glass

Our patented products, and other innovations for construction industry flat glass, have made us leaders in the technology applied to manufacture of this type of product, as well as in design and manufacture of custom tools for a wide range of applications.

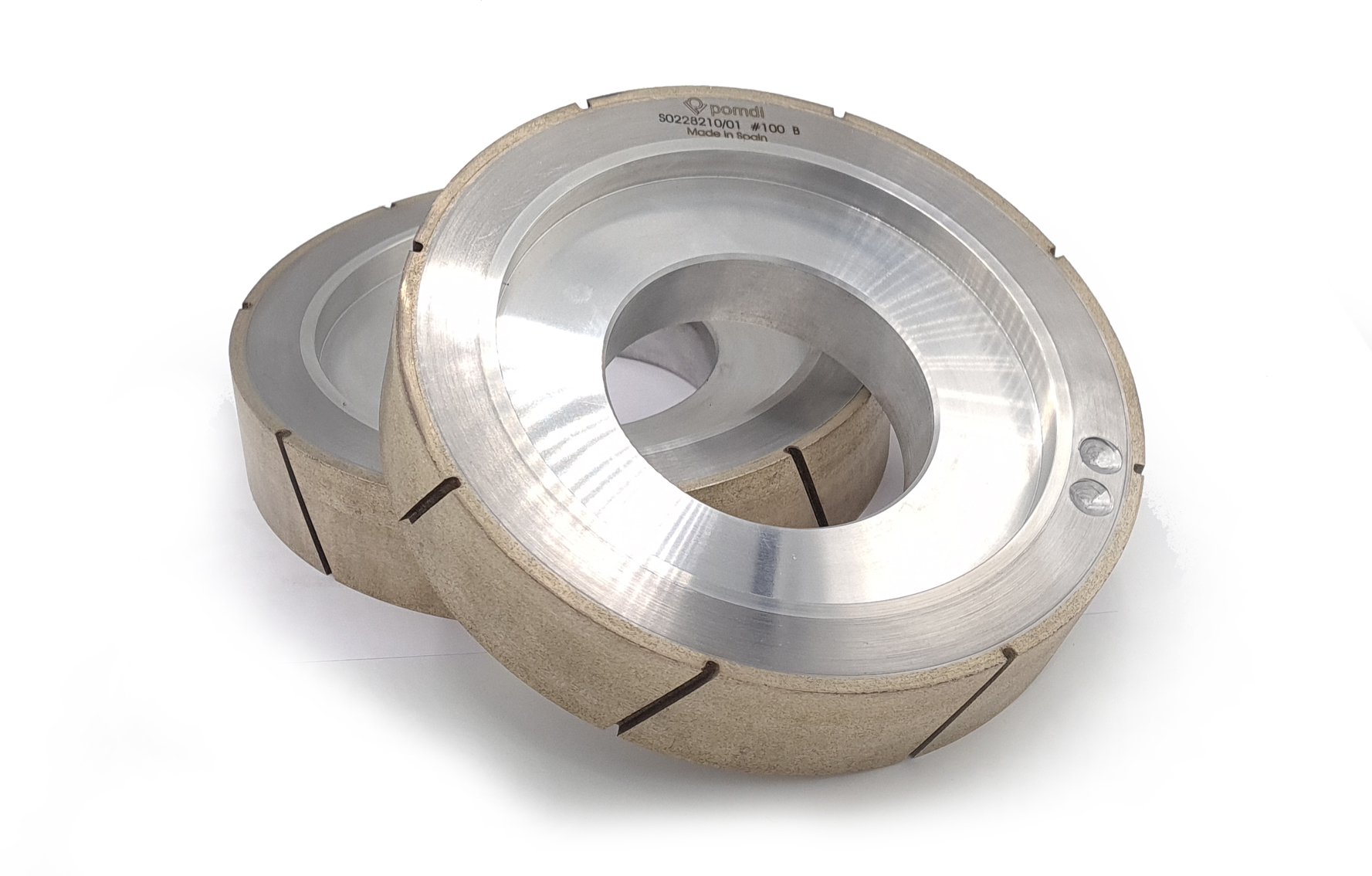

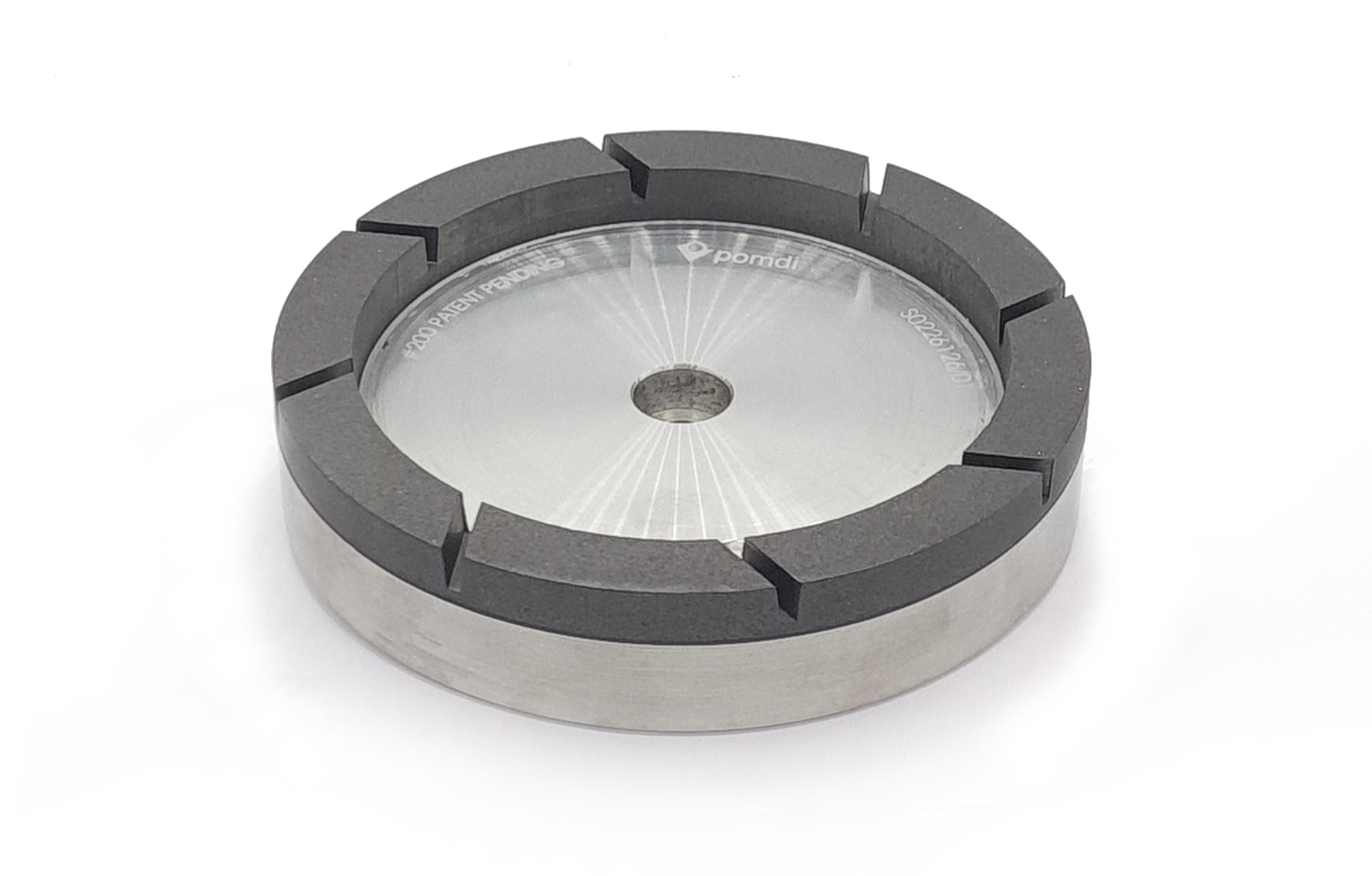

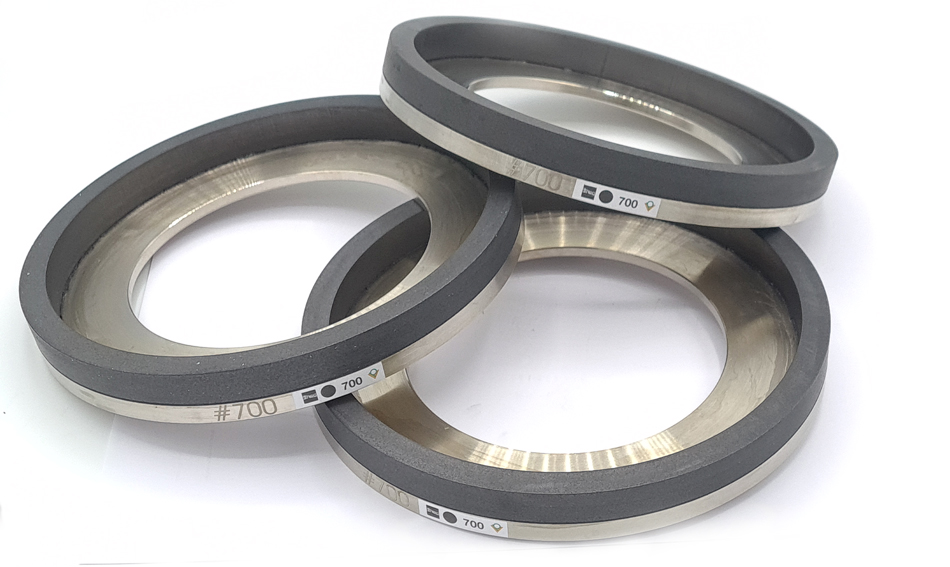

3NEO®, is our patented technology for cup grinding wheels used in edging and bevelling machines — as well as for reinforced peripheral grinding wheels used to edge laminar glass — that reduces tool wear with PVB.

Our INOX line for drilling and countersinking combines the best finish on the market with outstanding speed, features that have made it one of the world’s best-selling products.

Our line of high-performance and high cutting capacity milling tools completes our product range.

Applications for our architectural glass tools: bevelling, edging, drilling, countersinking, milling and cutting.

Automotive glass

We’re specialists in tools used to manufacture rear-view and wing mirrors.

For rear-view mirrors, we manufacture tools featuring our patented 3NEO® magnetic coupling technology. These tools are used in straight-line bevelling machines, generally with nine diamond wheels and nine felt and cerium oxide discs to deliver a flawless finish. After bevelling, the mirrors are edged either by hand or in CNC machines using ‘V’ grinding wheels to remove the sharp edges.

Wing mirrors, either straight or curved, are usually polished by hand or in CNC machines to remove any minor fractures caused by cutting.

Applications for our automotive glass tools: drilling, prismatic mirror bevelling and edge polishing.

Hollow glass

We actively contribute to manufacture of bottles, glasses and other hollow glassware. Our products are used in solutions ranging from mouth and stopper buffing to achieve a faultless seal — generally with 10% taper — through to glass flatting in automatic mills using various grain sizes to obtain a perfect buff.

We also manufacture glass-cutting tools used on complete glassware sets.

Applications for our hollow glass tools: buffing, flatting and grooving.

Unique products

We offer a range of unique glass-working products that deliver maximum quality and performance, with guaranteed supply, and support to deal with every eventuality.

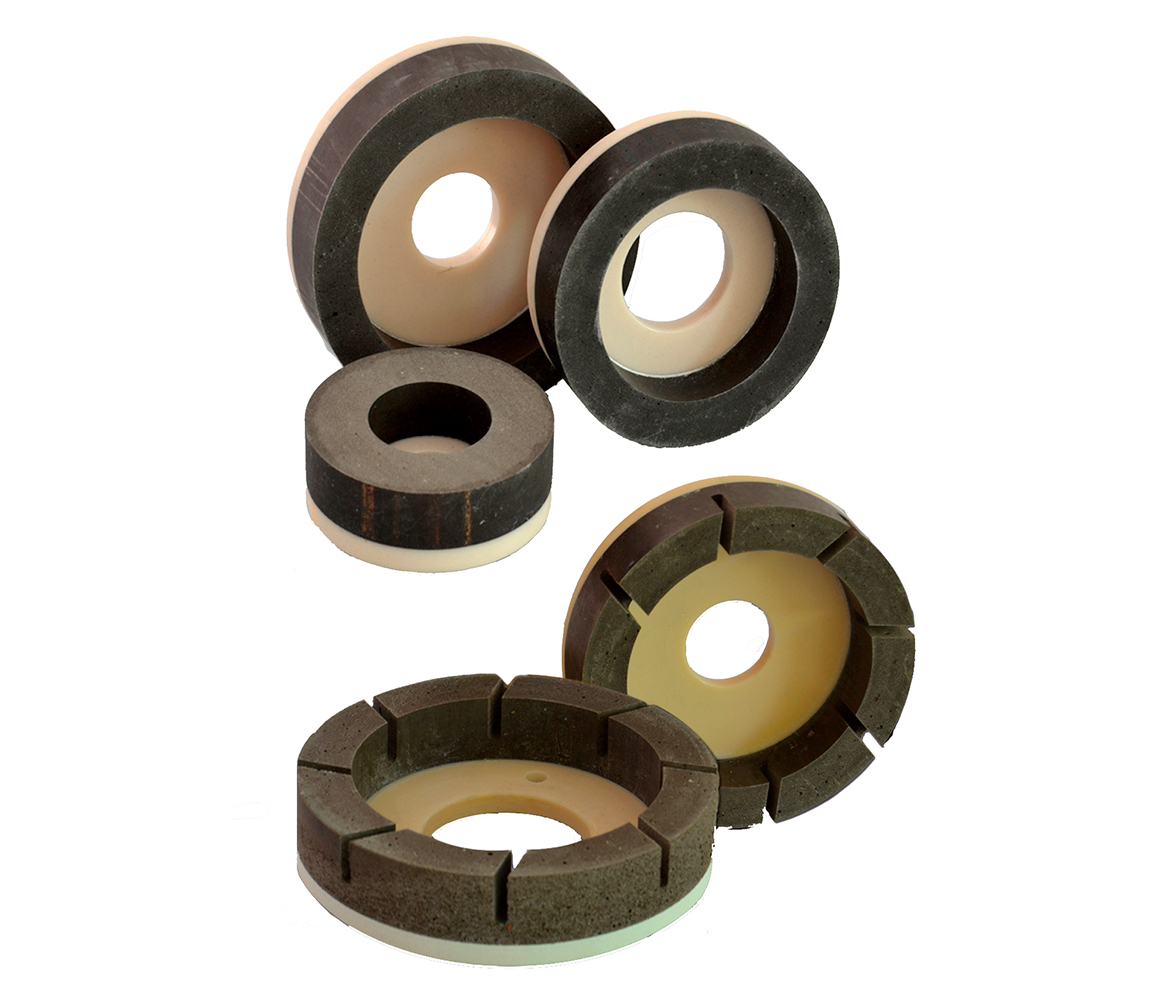

Artifex

Meeting our clients’ engineering requirements is our priority. Which is why we’ve teamed up with Artifex, working as the distributor on the Iberian Peninsula of their polishing wheels for edging machines used in the flat-glass and metal industries.

What’s more, thanks to this agreement, Pomdi and Artifex are jointly developing engineering solutions that feature our patented 3NEO® system, making it possible to equip clients’ machines with our magnetic coupling system for both diamond and polishing tools. Pomdi markets 3NEO® grinding wheels made with Artifex quality exclusively worldwide.

Cerium oxide

For glass edge and bevel polishing we market two types of cerium oxide:

Glossex Rosa: 25 kg tubs containing 5 x 5 kg sacks. Maximum quality for glass edging, and optimal for flat glass bevelling.

Glossex Blanco: 25 kg tubs containing 5 x 5 kg sacks. Maximum quality for flat glass bevelling. Also used on optics.

Glasweld scratch repair machine

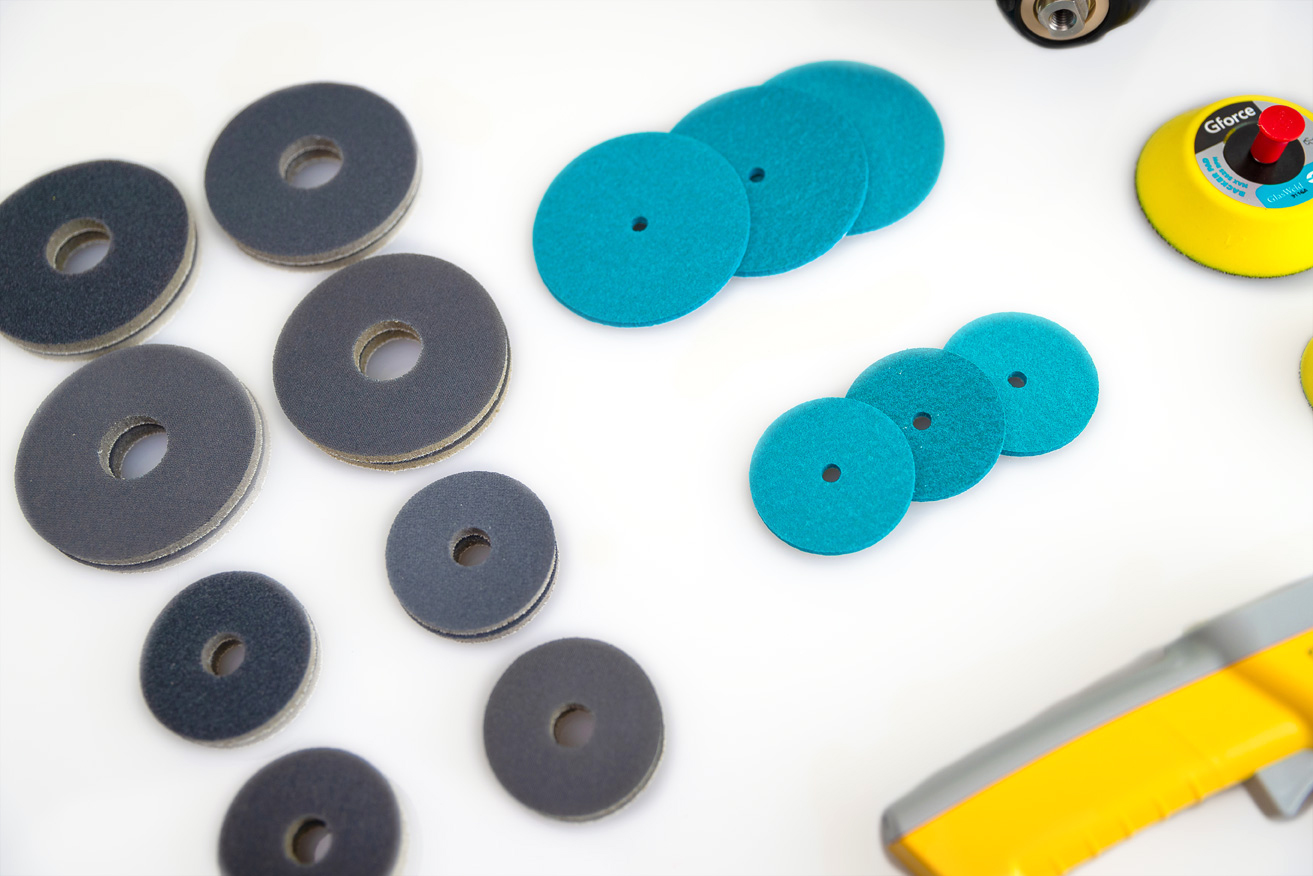

Glasweld's innovative scratch repair system, which we market throughout the Iberian Peninsula, is a portable device used to remove scratches or graffiti from glass. Two techniques are used:

Without optical deviation: Mainly for scraping, abrasion or scratching caused by other glass. It employs felts and a ‘magic’ compound that fills in the scratch and, using an increase in temperature as a catalyst, fully removes the scratch, leaving the glass as good as new, in flawless condition and without any optical deviation or distortion.

With optical deviation: Used for very deep scratches or to repair vandalized glass. This process uses abrasive sanding discs to remove the damaged glass before polishing it with a clearance compound. Because glass has been removed, optical deformation is inevitable, although it often won’t be visible to the naked eye.

This system is ideal for repairing tempered, laminated or curved glass either on site or in the workshop, avoiding the need to replace it and saving time and money.

Download the usage instructions here.

If you want to learn more: