3NEO®

Have you ever wondered why cup wheels are made as a single part?

If the grinding wheel shank doesn’t wear and is reusable, why not keep using it and only change the consumable?

With this in mind, and with the idea of meeting our clients' requirements and helping improve their productivity, we’ve developed our patented 3NEO® technology that cuts costs, part replacement times and stock levels.

3NEO® is a revolutionary technology patented by Pomdi that optimizes use of glass-working grinding wheels and diamond tools.

3NEO® allows you to reuse the grinding wheel’s shank after the diamond part is worn out, changing only the consumable — the diamond ring. You won’t have to buy the entire part, just the ring, reducing your costs and stock levels.

3NEO® technology is a sophisticated system used to couple the shank to the diamond ring, ensuring that they don't separate during operation but allowing removal with a single click when the consumable needs replacing.

3NEO® reduces the waste generated by replacing entire parts, minimizing your environmental impact and reducing your carbon footprint.

Lower your costs

The cost of changing only the consumable is lower than replacing the entire part. You pay solely for what you consume, without any wastage.

And you cut tool changeover time with our single-click system that doesn’t require you to remove a single screw.

Reduce your stock levels

With 3NEO® you only need to keep rings with different grain sizes. These rings are universal and fit any machine type. With our new 3NEO® technology you can use universal rings on any shank compatible with your machine.

Recommendations for use

If you are using 3NEO® for the first time

Users mounting a grinding wheel with the patented 3NEO® system for the first time are recommended to follow the steps indicated below:

- Unpack the 3NEO® shank.

- Thoroughly clean the surface to which the shank will be attached and apply a water-resistant grease to prevent build-up of glass residue. Pomdi recommends using brugerolas jet-70 grease.

- Attach the 3NEO® shank to the machine as if it were a complete grinding wheel.

- Apply a water-resistant grease to the surface of the shank to which the 3NEO® grinding ring will be attached.

- Attach the 3NEO® grinding ring to the shank, where it will be held in place by pomdi’s patented magnetic system.

- Once the 3NEO® system is assembled, seal the external join between the shank and the grinding ring with a water-resistant grease to prevent glass residue penetrating between the 3NEO® components and to ensure that this surface is kept as clean as possible ready for 3NEO® grinding ring changeover.

- Once the grinding wheel has been aligned and adjusted in the machine, it is ready for use.

Users replacing a worn 3NEO® grinding ring are recommended to follow the steps indicated below:

- Remove the worn 3NEO® grinding ring by levering it out using a slotted screwdriver. This will deactivate the magnetic field, freeing the 3NEO® grinding ring ready for replacement.

- Thoroughly clean the surface of the 3NEO® shank to which the new 3NEO® grinding ring will be attached.

- Once clean, apply a water-resistant grease to the surface of the shank to which the 3NEO® grinding ring will be attached. Pomdi recommends using brugerolas jet-70 grease.

- Attach the 3NEO® grinding ring to the shank, where it will be held in place by pomdi’s patented magnetic system.

- Once the 3NEO® system is assembled, seal the external join between the shank and the grinding ring with a water-resistant grease to prevent glass residue penetrating between the 3NEO® components and to ensure that this surface is kept as clean as possible ready for 3NEO® grinding ring changeover.

- Once the grinding wheel has been aligned and adjusted in the machine, it is ready for use.

Further information

| POS | 3NEO | Alternative 1 | Alternative 2 |

|---|---|---|---|

| 5/6 spindles- 3 muelas/wheels (1M 2R) | |||

| 1º | 3NEO 150x6x8 B-CONTINUO #80 | 3NEO 150x5x12 B-CONTINUO #80 | |

| 2º | 3NEO 150x15x10 B-LISA #230 | 3NEO 150x15x12 B-TURBO #230 | 3NEO 150x20x12 B-TURBO #230 |

| 3º | 3NEO 150x15x10 B-LISA #700 | 3NEO 150x15x12 B-TURBO #700 | 3NEO 150x20x12 B-TURBO #700 |

| 7/8 Spindles – 4 muelas/wheels (2M 2R) | |||

| 1º | 3NEO 150x6x8 B-CONTINUO #80 | 3NEO 150x5x12 B-CONTINUO #80 | |

| 2º | 3NEO 150x6x8 B-CONTINUO #120 | 3NEO 150x5x12 B-CONTINUO #120 | |

| 3º | 3NEO 150x15x10 B-LISA #230 | 3NEO 150x15x12 B-TURBO #230 | 3NEO 150x20x12 B-TURBO #230 |

| 4º | 3NEO 150x15x10 B-LISA #700 | 3NEO 150x15x12 B-TURBO #700 | 3NEO 150x20x12 B-TURBO #700 |

| 10 Spindles – 6 muelas/wheels (2M 4R) | |||

| 1º | 3NEO 150x6x8 B-CONTINUO #70 | 3NEO 150x5x12 B-CONTINUO #70 | |

| 2º | 3NEO 150x6x8 B-CONTINUO #80 | 3NEO 150x5x12 B-CONTINUO #80 | |

| 3º | 3NEO 150x15x10 B-LISA #140 | 3NEO 150x15x12 B-TURBO #140 | 3NEO 150x20x12 B-TURBO #140 |

| 4º | 3NEO 150x15x10 B-LISA #230 | 3NEO 150x15x12 B-TURBO #230 | 3NEO 150x20x12 B-TURBO #230 |

| 5º | 3NEO 150x15x10 B-LISA #500 | 3NEO 150x15x12 B-TURBO #500 | 3NEO 150x20x12 B-TURBO #500 |

| 6º | 3NEO 150x15x10 B-LISA #700 | 3NEO 150x15x12 B-TURBO #700 | 3NEO 150x20x12 B-TURBO #700 |

| 11 Spindles – 7 muelas/wheels (2M 5R) | |||

| 1º | 3NEO 150x6x8 B-CONTINUO #70 | 3NEO 150x5x12 B-CONTINUO #70 | |

| 2º | 3NEO 150x6x8 B-CONTINUO #80 | 3NEO 150x5x12 B-CONTINUO #80 | |

| 3º | 3NEO 150x15x10 B-LISA #140 | 3NEO 150x15x12 B-TURBO #140 | 3NEO 150x20x12 B-TURBO #140 |

| 4º | 3NEO 150x15x10 B-LISA #230 | 3NEO 150x15x12 B-TURBO #230 | 3NEO 150x20x12 B-TURBO #230 |

| 5º | 3NEO 150x15x10 B-LISA #500 | 3NEO 150x15x12 B-TURBO #500 | 3NEO 150x20x12 B-TURBO #500 |

| 6º | 3NEO 150x15x10 B-LISA #600 | 3NEO 150x15x12 B-TURBO #600 | 3NEO 150x20x12 B-TURBO #600 |

| 7º | 3NEO 150x15x10 B-LISA #700 | 3NEO 150x15x12 B-TURBO #700 | 3NEO 150x20x12 B-TURBO #700 |

| POS | 3NEO | Alternative 1 | Alternative 2 |

|---|---|---|---|

| 1º | 3NEO 150x7x8 B-CONTINUO #70 | ||

| 2º | 3NEO 150x10x13 B-LISA #170 | 3NEO 150x15x10 B-LISA #170 |

| POS | 3NEO | Alternative 1 | Alternative 2 |

|---|---|---|---|

| 4/5 spindles – 1 muela/wheel (1P) | |||

| 1º | 3NEO 150x7x6 C-CONTINUO #140 | 3NEO 150x15x6 C-LAM #140 | 3NEO 150x15x5 C-LYM #140 |

| 6/7 spindles- 2 muela/wheel (2P) | |||

| 1º | 3NEO 150x7x6 C-CONTINUO #100 | 3NEO 150x15x6 C-LAM #100 | 3NEO 150x15x5 C-LYM #100 |

| 2º | 3NEO 150x7x6 C-CONTINUO #200 | 3NEO 150x15x6 C-LAM #200 | 3NEO 150x15x5 C-LYM #200 |

| 6/7 spindles 45º – 2 muela/wheel (2P) | |||

| 1º | 3NEO 150x19x9 C-INGLETE #100 | 3NEO 150x14x7 C-INGLETE ECO #100 | |

| 2º | 3NEO 150x7x6 C-CONTINUO #200 | 3NEO 150x15x6 C-LAM #200 | 3NEO 150x15x5 C-LYM #200 |

| 2º | 3NEO 150x15x10 C-LISA #200 | 3NEO 150x15x12 C-TURBO #200 | |

| 8/9 spindles- 4 muela/wheel (2P + 2A) | |||

| 1º | 3NEO 150x7x6 C-CONTINUO #100 | 3NEO 150x15x6 C-LAM #100 | 3NEO 150x15x5 C-LYM #100 |

| 2º | 3NEO 150x7x6 C-CONTINUO #200 | 3NEO 150x15x6 C-LAM #200 | 3NEO 150x15x5 C-LYM #200 |

| 2º | 3NEO 150x15x10 C-LISA #200 | 3NEO 150x15x12 C-TURBO #200 | |

| AR | 3NEO 150x7x6 C-CONTINUO #230 ARISTA | 3NEO 130x7x6 C-CONTINUO #230 ARISTA | 3NEO 100x7x6 C-CONTINUO #230 ARISTA |

| AR | 3NEO 150x15x10 C-LISA #270 ARISTA | 3NEO 130x15x10 C-LISA #270 ARISTA | |

| 8/9 spindles 45º – 4 muela/wheel (2P + 2A) | |||

| 1º | 3NEO 150x19x9 C-INGLETE #100 | 3NEO 150x14x7 C-INGLETE ECO #100 | |

| 2º | 3NEO 150x7x6 C-CONTINUO #200 | 3NEO 150x15x6 C-LAM #200 | 3NEO 150x15x5 C-LYM #200 |

| 2º | 3NEO 150x15x10 C-LISA #200 | 3NEO 150x15x12 C-TURBO #200 | |

| AR | 3NEO 150x7x6 C-CONTINUO #230 ARISTA | 3NEO 130x7x6 C-CONTINUO #230 ARISTA | 3NEO 100x7x6 C-CONTINUO #230 ARISTA |

| AR | 3NEO 150x15x10 C-LISA #270 ARISTA | 3NEO 130x15x10 C-LISA #270 ARISTA | |

| 10/11 spindles – 5 muela/wheel (3P + 2A) | |||

| 1º | 3NEO 150x7x6 C-CONTINUO #100 | 3NEO 150x15x6 C-LAM #100 | 3NEO 150x15x5 C-LYM #100 |

| 2º | 3NEO 150x7x6 C-CONTINUO #140 | 3NEO 150x15x6 C-LAM #140 | 3NEO 150x15x5 C-LYM #140 |

| 3º | 3NEO 150x7x6 C-CONTINUO #200 | 3NEO 150x15x6 C-LAM #200 | 3NEO 150x15x5 C-LYM #200 |

| 3º | 3NEO 150x15x10 C-LISA #200 | 3NEO 150x15x12 C-TURBO #200 | |

| AR | 3NEO 150x7x6 C-CONTINUO #230 ARISTA | 3NEO 130x7x6 C-CONTINUO #230 ARISTA | 3NEO 100x7x6 C-CONTINUO #230 ARISTA |

| AR | 3NEO 150x15x10 C-LISA #270 ARISTA | 3NEO 130x15x10 C-LISA #270 ARISTA | |

| 10/11 45º spindles – 5 muela/wheel (3P + 2A) | |||

| 1º | 3NEO 150x19x9 C-INGLETE #100 | 3NEO 150x14x7 C-INGLETE ECO #100 | |

| 2º | 3NEO 150x7x6 C-CONTINUO #140 | 3NEO 150x15x6 C-LAM #140 | 3NEO 150x15x5 C-LYM #140 |

| 3º | 3NEO 150x7x6 C-CONTINUO #200 | 3NEO 150x15x6 C-LAM #200 | 3NEO 150x15x5 C-LYM #200 |

| 3º | 3NEO 150x15x10 C-LISA #200 | 3NEO 150x15x12 C-TURBO #200 | |

| AR | 3NEO 150x7x6 C-CONTINUO #230 ARISTA | 3NEO 130x7x6 C-CONTINUO #230 ARISTA | 3NEO 100x7x6 C-CONTINUO #230 ARISTA |

| AR | 3NEO 150x15x10 C-LISA #270 ARISTA | 3NEO 130x15x10 C-LISA #270 ARISTA | |

| 10/11 spindles – 7 muela/wheel (5P + 2A) | |||

| 1º | 3NEO 150x7x6 C-CONTINUO #100 | 3NEO 150x15x6 C-LAM #100 | 3NEO 150x15x5 C-LYM #100 |

| 2º | 3NEO 150x7x6 C-CONTINUO #140 | 3NEO 150x15x6 C-LAM #140 | 3NEO 150x15x5 C-LYM #140 |

| 3º | 3NEO 150x7x6 C-CONTINUO #200 | 3NEO 150x15x6 C-LAM #200 | 3NEO 150x15x5 C-LYM #200 |

| 3º | 3NEO 150x15x10 C-LISA #200 | 3NEO 150x15x12 C-TURBO #200 | |

| 4º | 3NEO 150x15x10 C-LISA #325 | 3NEO 150x15x12 C-TURBO #325 | |

| 5º | 3NEO 150x15x10 C-LISA #600 | 3NEO 150x15x12 C-TURBO #600 | |

| AR | 3NEO 150x7x6 C-CONTINUO #230 ARISTA | 3NEO 130x7x6 C-CONTINUO #230 ARISTA | 3NEO 100x7x6 C-CONTINUO #230 ARISTA |

| AR | 3NEO 150x15x10 C-LISA #270 ARISTA | 3NEO 130x15x10 C-LISA #270 ARISTA | |

| 10/11 45º spindles – 7 muela/wheel (5P + 2A) | |||

| 1º | 3NEO 150x19x9 C-INGLETE #100 | 3NEO 150x14x7 C-INGLETE ECO #100 | |

| 2º | 3NEO 150x7x6 C-CONTINUO #140 | 3NEO 150x15x6 C-LAM #140 | 3NEO 150x15x5 C-LYM #140 |

| 3º | 3NEO 150x7x6 C-CONTINUO #200 | 3NEO 150x15x6 C-LAM #200 | 3NEO 150x15x5 C-LYM #200 |

| 3º | 3NEO 150x15x10 C-LISA #200 | 3NEO 150x15x12 C-TURBO #200 | |

| 4º | 3NEO 150x15x10 C-LISA #325 | 3NEO 150x15x12 C-TURBO #325 | |

| 5º | 3NEO 150x15x10 C-LISA #600 | 3NEO 150x15x12 C-TURBO #600 | |

| AR | 3NEO 150x7x6 C-CONTINUO #230 ARISTA | 3NEO 130x7x6 C-CONTINUO #230 ARISTA | 3NEO 100x7x6 C-CONTINUO #230 ARISTA |

| AR | 3NEO 150x15x10 C-LISA #270 ARISTA | 3NEO 130x15x10 C-LISA #270 ARISTA | |

Flat edge

Metal rings

C-Inglete Plano

C-Inglete

C-Inglete Eco

C-Lam

C-Intur

C-Lym

C-Contínuo

Resin rings

C-Lisa

C -Turbo

C-Turbox

C -Coolix

Bevel

Metal rings

B-Contínuo

Resin rings

B-Lisa

B -Turbo

B-Intur

B -Coolix

We have adapted our 3NEO® magnetic system to the rubber and cerium wheels of the most important manufacturers in the world. Currently, we supply our customers and distributors exclusively with 3NEO® magnetic mounts and rings for gloss engines from companies such as Germany’s Artifex and Italy’s RBM.

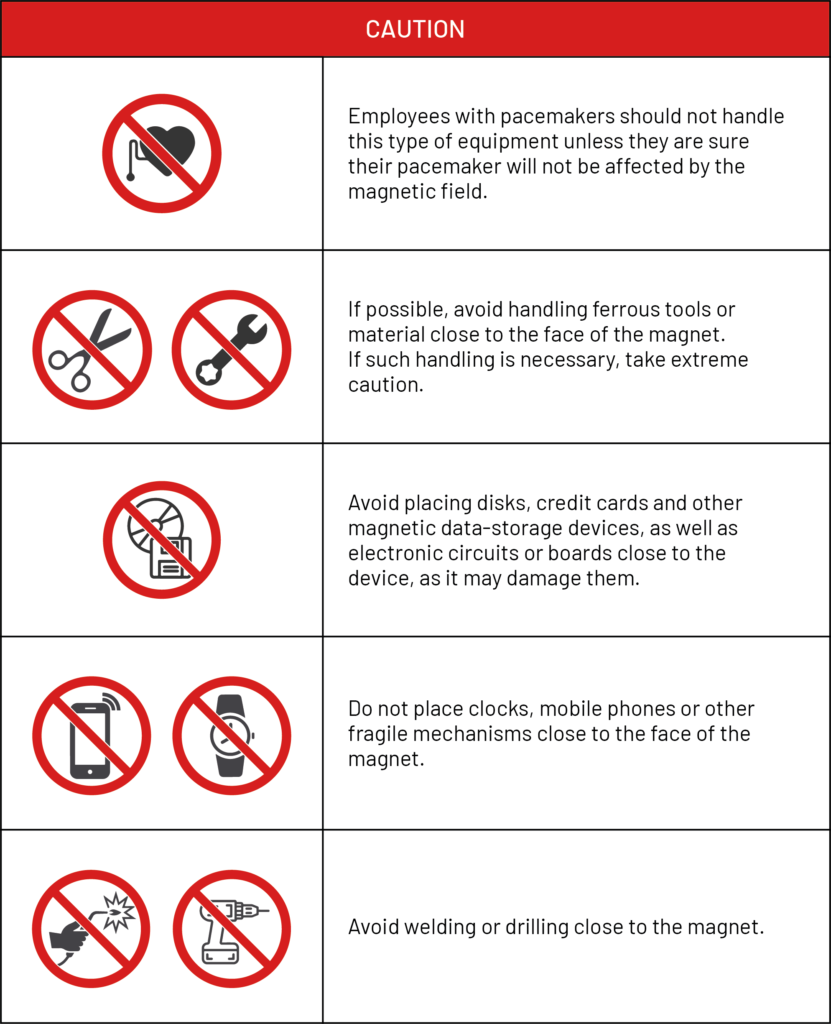

The magnet produces a constant magnetic field. Therefore, in all cases:

- Use and/or handling of permanent magnets is not advised for people with pacemakers.

- For safety reasons, people with ferromagnetic metal implants should remain a minimum distance of 2 metres away from the magnet.